Injection moulded components in 5 days…

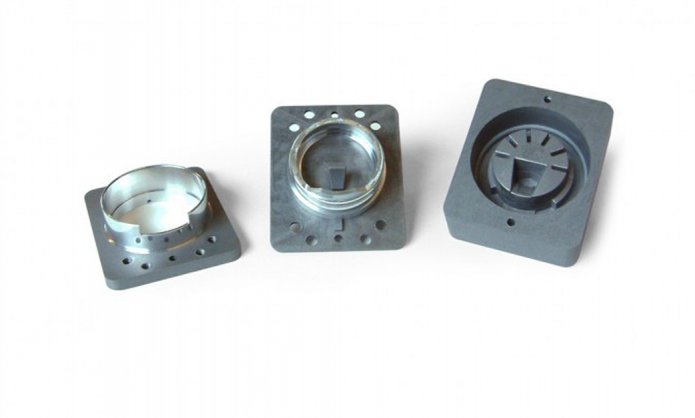

It would take other companies two weeks, but using modern rapid tooling technology, Minima has the capability to design and build tooling for plastic injection moulded parts in just a few days. Production-ready parts can then be injection moulded using final materials with our in-house facilities.

Kwik-tool has been driven by the need to reach further than rapid prototyping and generate multiples of precision injection-moulded components using production grade materials, in a matter of days. This is invaluable for enabling full evaluation of design performance prior to buseinss partner investment in production tooling.

Kwik tool has been devised to facilitate design changes. Based on a composite material and using a modular approach, the tool offers ultimate flexibility, whilst delivering appropriate production grade materials and tolerances. It enables revisions to be implemented quickly and easily – typically within 5 days.

This swift and cost-saving product-tuning can ensure that the designed product is fit for purpose and fit for manufacture at the same time as reducing the all-important journey time to market.